The forced-draft, cast iron Series LC/LCE™ boiler can be equipped with efficient burners for applications requiring gas, oil or combination gas/oil firing. There are 22 commercial sizes available for hot water or steam applications with inputs of 686 MBH up to 4,663 MBH, and thermal efficiencies of up to 83.7%. The advanced design allows for simpler installation using flex-seal gaskets and individual draw rods, as well as easy access to the boiler via top and front plates for inspection and cleaning. Optional tankless coils can be added for production of domestic hot water.

Type: Commercial

Construction: Cast Iron

Fuel: Oil, Gas, Gas/Oil-Fired

Input: 686 to 4,663 MBH

Output: 547 to 3,777 MBH

Venting: Forced Draft

Trim: Water or Steam

Combustion: Power Burner

All product installation manuals and technical literature is intended solely for professional installers and any installation or maintenance techniques described in any of this literature should not be attempted by homeowners. Always contact a professional for installation, maintenance and service.

| BSDS – LC™ & LCE™ Gordon Piatt R (45.48K) |

| BSDS – LC™ Beckett CF (103.38K) |

| BSDS – LC™ Beckett CG (703.77K) |

| BSDS – LC™ Carlin CRD & FFD (97.92K) |

| BSDS – LC™ Power Flame C (134.14K) |

| BSDS – LC™ Power Flame JRA (81.46K) |

| BSDS – LC™ Power Flame NPM (68.77K) |

| BSDS – LC™ Webster JB (135.34K) |

| Catalog Literature – Series LC™ & LCE™ (2.44M) |

| IO&M Manual – Series LC™ & LCE™ Steam (5.94M) |

| IO&M Manual – Series LC™ Water (3.64M) |

| Product Photo – Series LC™ (1.13M) |

| Sizing For Condensate Receiver Literature (72.71K) |

| Suggested Specs – Series LC™ & LCE™ (108.85K) |

| User’s Manual – Series SC™ & Series LC™ (441.20K) |

| Warranty – Commercial (53.45K) |

| Warranty – Extended Warranty (2.19M) |

Series LC/LCE™ | Water Content | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model Number | Oil Input | Gas Input, MBH | Net Ratings 4 | Oil | Gas | Steam, Gal | Water, Gal | |||||||

| GPH | MBH | Steam, sqft | Steam 3 , MBH | Water 2 , MBH | Combustion Efficiency 5 , % | Thermal Efficiency 5 , % | Combustion Efficiency 5 , % | Thermal Efficiency 5 , % | ||||||

| LC-04 | 4.75 | 665 | 686 | 1,708 | 410 | 476 | 83.7 | 82.2 | 81.2 | 79.8 | 40.57 | 50.65 | ||

| LC-05R | 5.60 | 784 | 808 | 2,029 | 487 | 564 | 83.7 | 82.8 | 81.2 | 80.3 | 47.29 | 59.05 | ||

| LC-05 | 6.10 | 854 | 881 | 2,208 | 530 | 615 | 83.7 | 82.8 | 81.2 | 80.3 | 47.29 | 59.05 | ||

| LC-06 | 7.50 | 1,050 | 1,077 | 2,713 | 651 | 755 | 83.7 | 83.1 | 81.1 | 80.6 | 54.01 | 67.45 | ||

| LC-07 | 8.80 | 1,232 | 1,273 | 3,217 | 772 | 895 | 83.6 | 83.3 | 81.1 | 80.8 | 60.73 | 75.85 | ||

| LC-08 | 10.20 | 1,428 | 1,469 | 3,717 | 892 | 1,034 | 83.6 | 83.5 | 81.1 | 81.0 | 67.45 | 84.25 | ||

| LC-09 | 11.60 | 1,624 | 1,664 | 4,250 | 1,020 | 1,174 | 83.6 | 83.6 | 81.1 | 81.1 | 74.17 | 91.65 | ||

| LC-10 | 12.80 | 1,792 | 1,860 | 4,804 | 1,153 | 1,314 | 83.6 | 83.7 | 81.1 | 81.2 | 80.89 | 101.05 | ||

| LC-11 | 14.20 | 1,988 | 2,056 | 5,367 | 1,288 | 1,454 | 83.6 | 83.8 | 81.1 | 81.3 | 87.61 | 109.45 | ||

| LC-12 | 15.60 | 2,184 | 2,252 | 5,917 | 1,420 | 1,593 | 83.6 | 83.9 | 81.1 | 81.4 | 94.33 | 117.85 | ||

| LCE-13 | 17.00 | 2,380 | 2,464 | 6,358 | 1,526 | N/A | 83.5 | 82.2 | 81.0 | 79.8 | 101.05 | — | ||

| LCE-14 | 18.40 | 2,576 | 2,657 | 6,875 | 1,650 | N/A | 83.5 | 82.5 | 81.0 | 80.0 | 107.77 | — | ||

| LCE-15 | 19.80 | 2,772 | 2,850 | 7,388 | 1,773 | N/A | 83.5 | 82.6 | 81.0 | 80.2 | 114.49 | — | ||

| LCE-16 | 21.00 | 2,940 | 3,043 | 7,908 | 1,898 | N/A | 83.5 | 82.8 | 81.0 | 80.3 | 121.21 | — | ||

| LCE-17 | 22.50 | 3,150 | 3,236 | 8,421 | 2,021 | N/A | 83.5 | 82.9 | 81.0 | 80.4 | 127.93 | — | ||

| LCE-18 | 24.00 | 3,360 | 3,429 | 8,938 | 2,145 | N/A | 83.5 | 83.1 | 81.0 | 80.6 | 134.65 | — | ||

| LCE-19 | 25.00 | 3,500 | 3,622 | 9,454 | 2,269 | N/A | 83.5 | 83.2 | 81.0 | 80.7 | 141.37 | — | ||

| LCE-20 | 26.50 | 3,710 | 3,815 | 9,971 | 2,393 | N/A | 83.5 | 83.3 | 81.0 | 80.8 | 148.09 | — | ||

| LCE-21 | 28.00 | 3,920 | 4,027 | 10,533 | 2,528 | N/A | 83.6 | 83.3 | 81.1 | 80.8 | 154.81 | — | ||

| LCE-22 | 29.50 | 4,130 | 4,239 | 11,096 | 2,663 | N/A | 83.6 | 83.4 | 81.1 | 80.9 | 161.53 | — | ||

| LCE-23 | 31.00 | 4,340 | 4,451 | 11,658 | 2,798 | N/A | 83.7 | 83.5 | 81.2 | 81.0 | 168.25 | — | ||

| LCE-24 | 32.50 | 4,550 | 4,663 | 12,217 | 2,932 | N/A | 83.7 | 83.5 | 81.2 | 81.0 | 174.97 | — | ||

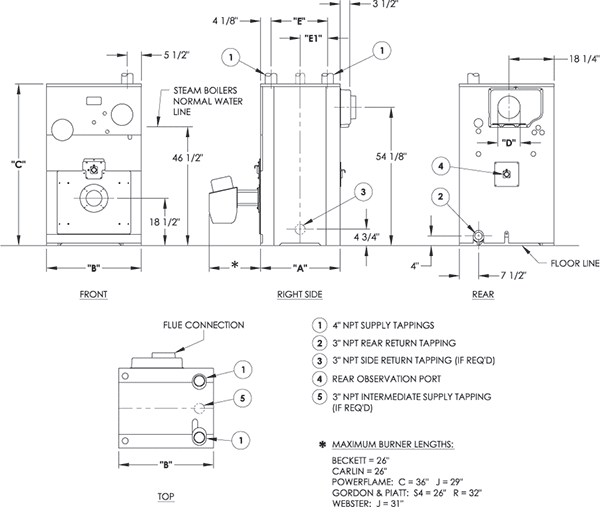

Series LC™ Boiler Dimensions

| Boiler Model Number | Jacket Depth “A” | Jacket Width “B” | Jacket Height “C” | Flue Size “D” | Distance Between Tappings* | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| “E” | Water | Steam | ||||||||

| “E1” | “E1” | “E2” | “E3” | “E4” | ||||||

| LC-04 | 25-15/16″ | 37″ | 63″ | 9″ | 16-1/2″ | — | — | — | — | — |

| LC-05R | 31″ | 37″ | 63″ | 9″ | 21-9/16″ | — | — | — | — | — |

| LC-05 | 31″ | 37″ | 63″ | 9″ | 21-9/16″ | — | — | — | — | — |

| LC-06 | 36-1/16″ | 37″ | 63″ | 10″ | 26-5/8″ | — | — | — | — | — |

| LC-07 | 41-1/8″ | 37″ | 63″ | 10″ | 31-11/16″ | — | — | — | — | — |

| LC-08 | 46-5/16″ | 37″ | 63″ | 10″ | 36-13/16″ | 15-13/16″ | — | — | — | — |

| LC-09 | 51-3/8″ | 37″ | 63″ | 12″ | 41-7/8″ | 20-15/16″ | — | — | — | — |

| LC-10 | 56-7/16″ | 37″ | 63″ | 12″ | 46-15/16″ | 20-15/16″ | — | — | — | — |

| LC-11 | 61-1/2″ | 37″ | 63″ | 12″ | 52″ | 26″ | 26″ | — | — | — |

| LC-12 | 66-9/16″ | 37″ | 63″ | 12″ | 57-1/8″ | 26″ | 26″ | — | — | — |

Apply Prefix”O” for oil—”G” for gas—”GO” for gas-oil.

The manufacturer should be consulted before selecting a boiler for installations having unusual piping and pickup requirements, such as intermittent system operation,

extensive piping, etc. For forced hot water heating systems where the boiler and all the piping are within the area to be heated, the boiler may be selected on the

basis of its Gross Output.

* Dimensions are approximate.

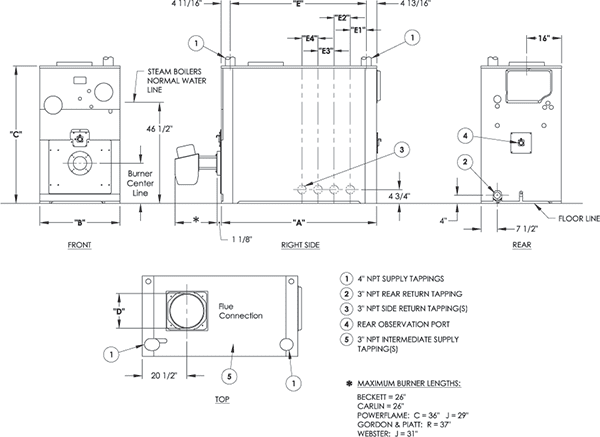

Series LCE™ Boiler Dimensions

| Boiler Model Number | Jacket Depth “A” | Jacket Width “B” | Jacket Height “C” | Flue Size “D” | Distance Between Tappings* | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| “E” | Water | Steam | ||||||||

| “E1” | “E1” | “E2” | “E3” | “E4” | ||||||

| LCE-13 | 71-3/4″ | 37″ | 63″ | 14″ | 62-3/16″ | — | 36-3/16″ | — | — | — |

| LCE-14 | 76-13/16″ | 37″ | 63″ | 14″ | 67-1/4″ | — | 20-5/16″ | 20-5/16″ | — | — |

| LCE-15 | 81-7/8″ | 37″ | 63″ | 14″ | 72-5/16″ | — | 26″ | 20-5/16″ | — | — |

| LCE-16 | 86-15/16″ | 37″ | 63″ | 14″ | 77-7/16″ | — | 26″ | 25-7/16″ | — | — |

| LCE-17 | 92-1/8″ | 37″ | 63″ | 14″ | 82-1/2″ | — | 20-5/16″ | 20-5/16″ | 15-1/4″ | — |

| LCE-18 | 97-3/16″ | 37″ | 63″ | 16″ | 87-9/16″ | — | 20-5/16″ | 20-5/16″ | 20-5/16″ | — |

| LCE-19 | 102-1/4″ | 37″ | 63″ | 16″ | 92-5/8″ | — | 20-5/16″ | 20-5/16″ | 25-7/16″ | — |

| LCE-20 | 107-7/16″ | 37″ | 63″ | 16″ | 97-3/4″ | — | 20-5/16″ | 20-5/16″ | 15-1/4″ | 15-1/4″ |

| LCE-21 | 112-1/2″ | 37″ | 63″ | 16″ | 102-13/16″ | — | 20-5/16″ | 20-5/16″ | 20-5/16″ | 15-1/4″ |

| LCE-22 | 117-9/16″ | 37″ | 63″ | 16″ | 107-7/8″ | — | 20-5/16″ | 20-5/16″ | 20-5/16″ | 20-5/16″ |

| LCE-23 | 122-5/8″ | 37″ | 63″ | 16″ | 112-15/16″ | — | 26″ | 20-5/16″ | 20-5/16″ | 20-5/16″ |

| LCE-24 | 127-11/16″ | 37″ | 63″ | 16″ | 118-1/16″ | — | 26″ | 20-5/16″ | 20-5/16″ | 25-7/16″ |

Apply Prefix”O” for oil—”G” for gas—”GO” for gas-oil.

The manufacturer should be consulted before selecting a boiler for installations having unusual piping and pickup requirements, such as intermittent system operation,

extensive piping, etc. For forced hot water heating systems where the boiler and all the piping are within the area to be heated, the boiler may be selected on the

basis of its Gross Output.

* Dimensions are approximate.